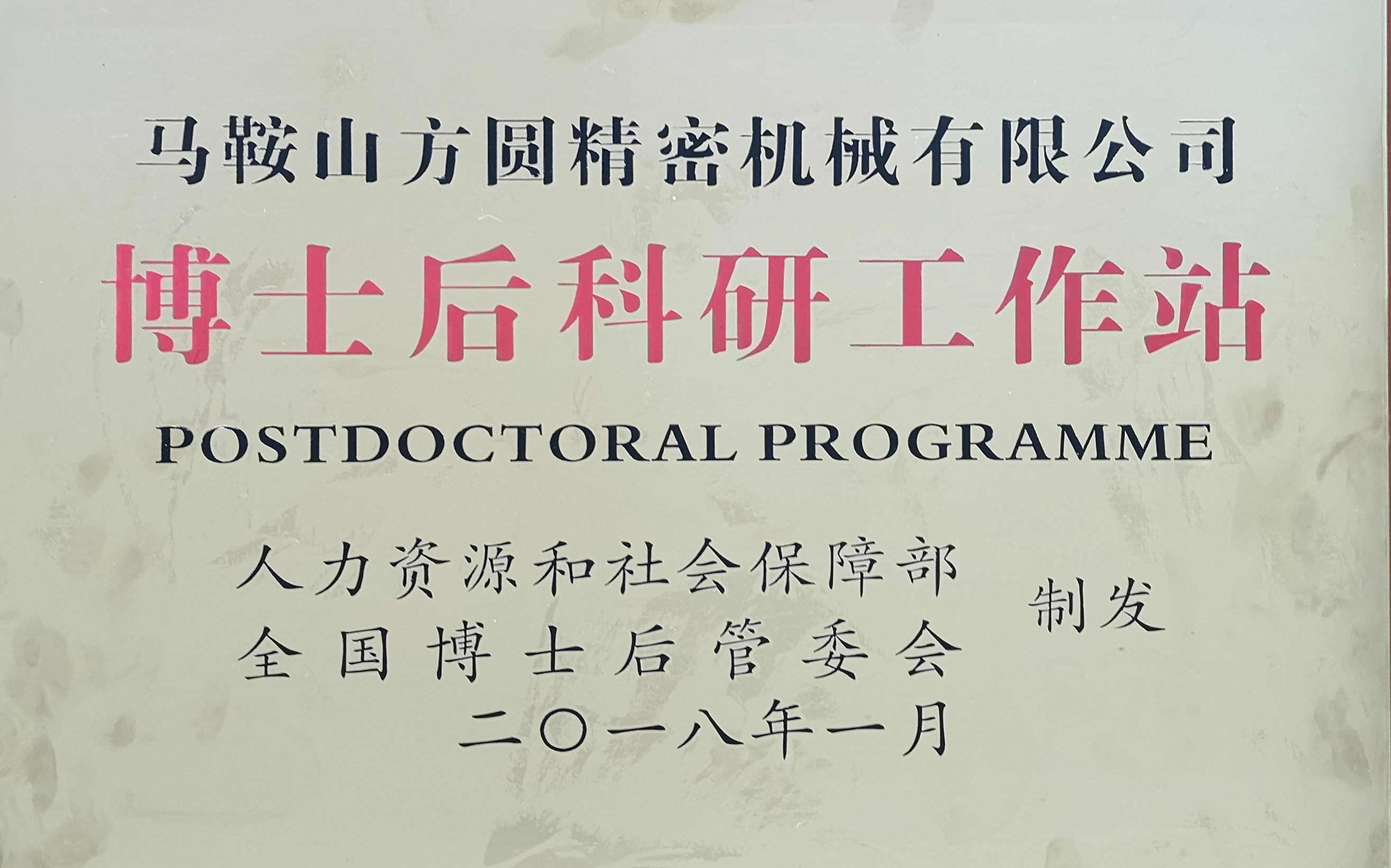

National Postdoctoral Research Workstation

Fangyuan Company uses postdoctoral research workstations as a platform and collaborates with domestic university Nanjing University of Technology to carry out industry university research cooperation on slewing bearings and their equipment, promoting the transformation and upgrading of manufacturing enterprises and achieving "China's intelligent manufacturing".

The School of Mechanical and Power Engineering at Nanjing University of Technology has established the Jiangsu Provincial Key Laboratory for Digital Manufacturing and Control of Industrial Equipment and the Jiangsu Provincial Engineering Research Center for CNC Special Equipment. A large amount of basic research work has been carried out on three-dimensional parametric modeling, mechanical processing technology, structural static and dynamic characteristics analysis, experimental equipment development, condition monitoring, life assessment methods, experimental methods, and other aspects related to rotary bearing products and rotary bearing manufacturing equipment.